|

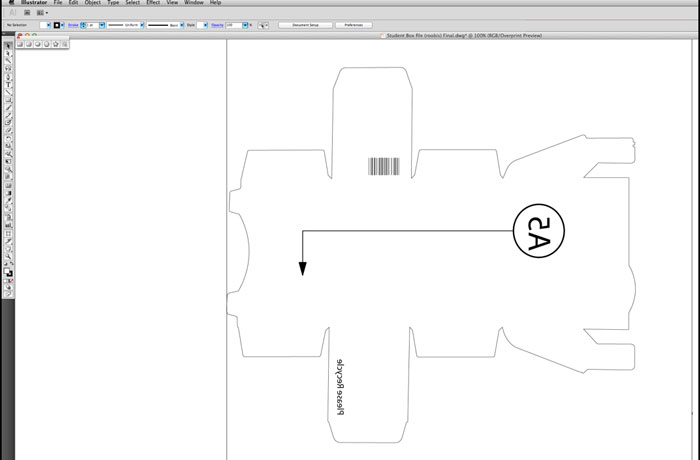

This 2012 Faculty Incentive Grant project, proposed and conducted by one of our Art Instructors, began with students assisting him with the development of an Adobe Illustrator (design program) file that was sent to MBS Fabricating and Coating to laser cut out of 1/4″ mild steel. The students were placed in the role of operating as studio assistants, a job that almost every artist has in the early years of their career.

|

|

|

Once MBS had completed the cutting and bending, they delivered the piece to Welding Instructor Al Lofland’s class on the Statesville Campus at Mitchell Community College. The final pieces were welded on and footers were attached in order to secure the piece to pre-poured concrete pads. |

|

Following the completion of the welding, Keco Coatings picked up the work from campus, powder coated it, then delivered it to its location in front of the Wallace House. |

|

|

Two concrete pads were pre-poured for the piece and, after the piece was unloaded from the truck, it was attached to the pads. |

|

Following the placement, the Art Instructor discussed the relationship of the piece to its surrounding landscape and addressed the possibility of adding another color, what color might be most effective, and which details might be created or highlighted with this color.

The process proved to be effective as a tool to inform the students about what it is like to fabricate and install an outdoor sculpture. |

Hours of Operation

Monday 8:00 am – 5:00 pm

Tuesday 8:00 am – 5:00 pm

Wednesday 8:00 am – 5:00 pm

Thursday 8:00 am – 5:00 pm

Friday 8:00 am – 5:00 pm

Saturday Closed

Sunday Closed